You are quite likely to come across a

wide range of rollers in package industries that are individually designed to

serve their specific sets of operations and stay true to their purpose. It is

of immense importance that the suppliers or the manufacturers of the packaging

material that you have chosen have equipped their companies with highly

qualified rollers.

Several international standards are

set to prove the validity of a product based on its abilities and capability to

perform a given task on satisfactory levels.

Acknowledging The Sorts Of Rollers In The Industries

Some of the most widely known and

used rollers of all time are rubber bow

roller, bow rollers, bow banana roller, expander roller, and spreader roller. Before comprehending

their importance and understanding the conduct of their work, here are a few

tips and suggestions that you must want to keep in mind.

The packaging equipment is available

in multiple ranges of sizes and dimensions to meet the necessities of each

enterprise that needs a customized set of packaging solutions. Your

requirements must be thoroughly understood before any conclusions are made or

decisions finalized.

Figure Out The Necessities Of Your Industrial Resources

A reliable manufacturer or agency

would always spend a significant amount of time when it comes to attending your

routine conduct of working procedures and set up a tentative plan to furnish

your business with only required and essential equipment.

The selection criteria of packaging

equipment are strictly based on the elements that are going to be used in the

packaging procedure of material that your deals are generally based on.

Installing the most relevant

machinery could be of unmatchable assistance when it comes to the automation of

your processes. It can expand your sales and also help you to advance towards

global level business standards. You can enhance the way you trade and deal

with your potential clients with the seamless assistance of automated systems.

·

The Unswerving Support Of A

Dependable Rubber Bow Roller

A rubber bow roller is used to remove wrinkles from the surfaces of

various packaging materials that include a wide range of plastic, laminating paper

and various types of foils and films that are to be used in packaging of

fragile goods as well.

You can easily select the most

effective bow roller based on your necessities and amount that is going to be

used in wrapping or coiling of materials.

·

The Importance Of Bow Rollers In

Reliable Packaging

Once you are done installing the

required sets of bow rollers, your

company is ready to move forward with the further procedures that are

consistently used. The bow rollers that are included in your machinery must be

taken care of and looked after by professionals that have expertise in the

field of maintaining them and replacing the components that need

restoration.

These rollers are generally held

against their holders with a firm grip that is of equal importance too and

needs timely assessment and maintenance.

·

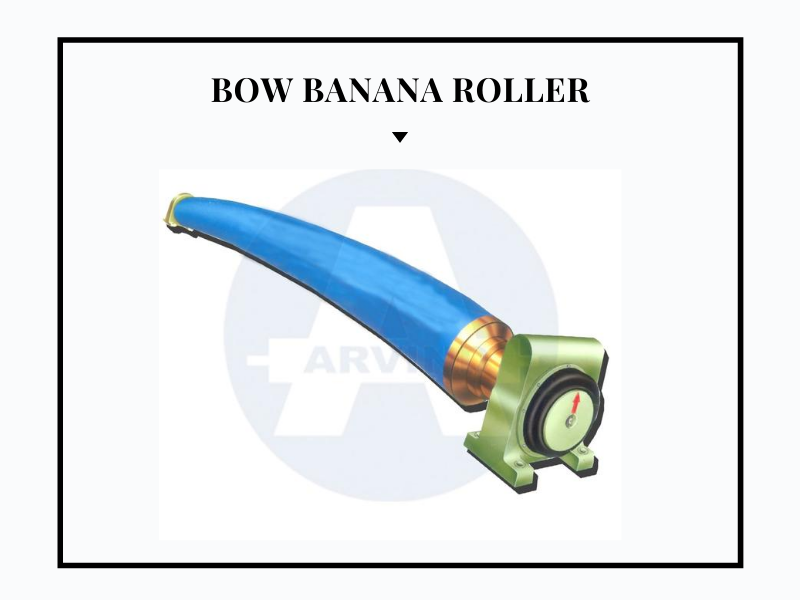

An Inkling That Concerns Banana Bow

Rollers And Its Essentiality

Banana Bow Rollers are also widely known across the packaging industries as Expander Bars Bow Roller. The prime

purpose of this specific type of roller is to help the surface of your

packaging material to get rid of the unnecessary and harmful wrinkles that are

caused.

These rollers are used while

printing, laminating and on many occasions even swift processing of the

material. It is also proven to be a great tool for the winding and unwinding of

various materials.

·

Widely Helpful Expander And Spreader Rollers

In The Industries

Expander Rollers are available in various types and each type is pronounced to be serving

its purpose well. These rollers are designed to benefit industries with high

performance and extremely strong design that can last the test of time and

durability.

The purpose of a spreader roller could be said to be on a similar base on that of

expander rollers. It is used to spread a material and set it free of creases

while unwinding it.

In Conclusion,

the low maintenance properties of standard equipment are of a great

cost-efficient and profitable notion to your enterprise. You should consider

comparing various rollers and taking your time when it comes to selecting one

for the betterment of your enterprise. Mechanical automation of your service

could undoubtedly take you business to unmatchable heights in no time.

Advancing towards perfection is made multiple times easier with today’s

available packing technology.