Learn About Rubber Roller Grinding Machine From Intro To Benefits

Industrial Roller Company is labelled as significant Manufacturers, India and exporter of the immense scope of Heavy Nip Rollers for the Textile industry. We accept that quality talks itself about the item. Considering distinctive application which meets current and most recent mechanical action of the material industry we have planned nip rollers with most present-day specialized highlights.

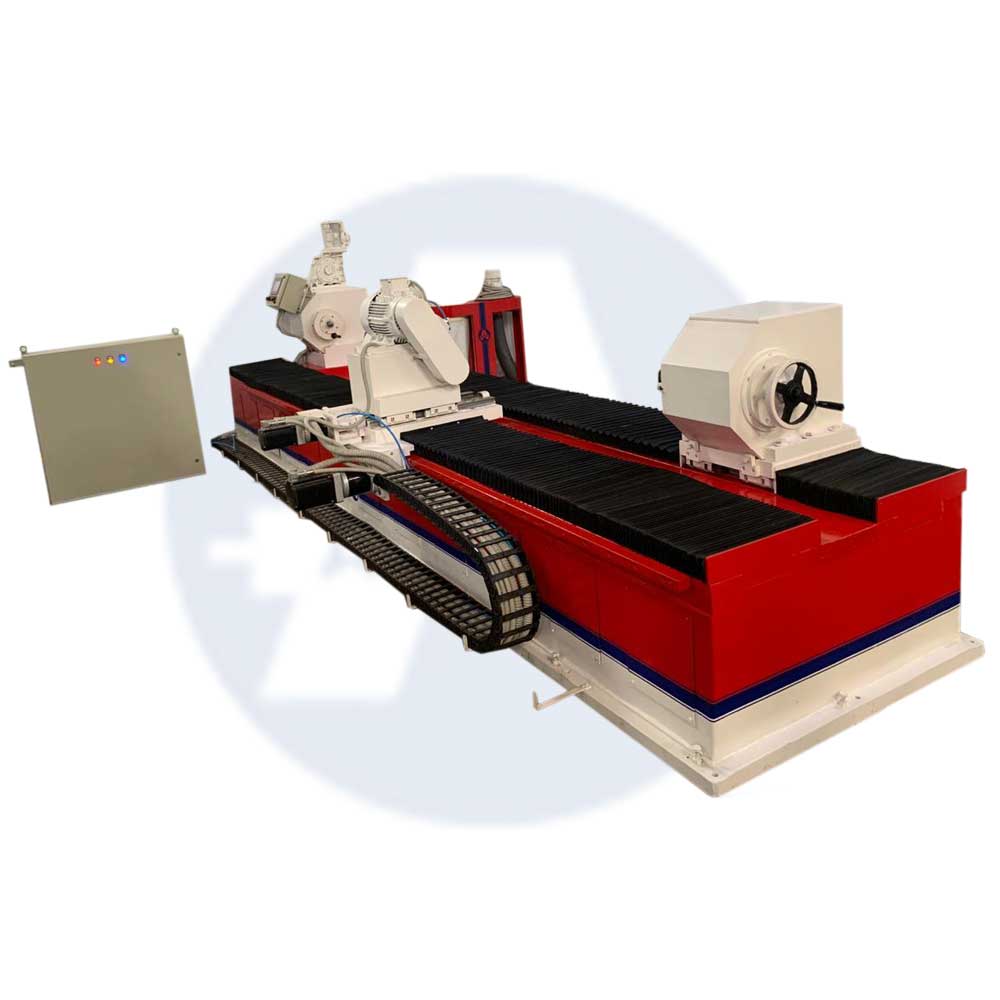

These Rollers made for better-scraped spot opposition additionally give great mileage obstruction for successful execution. Here, we discuss everting about rubber roller grinding machine and its introduction, application, features, working principle.

Introduction

The Rubber Roller Grinding Machine has broad application in the ventures of mining, building materials, compound industry, metallurgy, and so forth The roller smasher can squash materials with canter hardness or not exactly centre hardness into auxiliary or fine granularity, for example, pulverizing mineral, rocks, coke, coal, slag, scoria, and flame resistant material and so forth

Main Applications:

Mainly utilized for the devastating of medium or lower-hardness mines and shakes with medium or lower unbending nature in mine choice, synthetic substances, concrete and building materials mechanical creation.

Working Principle

The fixed piece of the roller and mobile roller is driven by the engine by means of reducer and v-belt, the crude materials fall into the part between the two rollers from the channel of the machine. The two rollers pivot internally at the same time. The materials are expelled, squashed and ground, at that point the finished results come out from the lower part of this smasher.

Sorts of Roller Grinding Machine

As indicated by the quantity Rubber Roller Grinding Machine, it tends to be partitioned into single-move smasher, twofold move smasher, three-move smasher and four-move smasher.The single-move smasher is basically utilized for coarse squashing of strong materials with medium hardness.

The four-move smasher is predominantly appropriate for the fine pulverizing of hard and medium-hard materials with compressive strength under 200Mpa and moistness under 30%.

- Simple structure and simple support

The normalized measured consolidated tooth plate is exchangeable and general, which extraordinarily diminishes the substitution pattern of the tooth plate and lessens working expenses.

- Low powder rate and great molecule size

The normalized secluded consolidated tooth plate is tradable and general, which significantly diminishes the substitution pattern of the tooth plate and decreases working expenses.

- Large pounding proportion

The normalized particular joined tooth plate is exchangeable and all-inclusive, which extraordinarily diminishes the substitution pattern of the tooth plate and lessens working expenses.

- Hard insurance gadget

The roller smasher is outfitted with a hard security gadget. At the point when the size is enormous or solid, the spring is packed, and the versatile roller retreats to expand the release port. After the material is released, the mobile roller returns under the spring tension.

Features of Roller Grinding Machine

- Innovatively Designed: NO Skilled Operator required

- Specially created for venture Down and Re Grinding of elastic Roller and speedy Change Sleeve.

- Holding on Bearing Sizes

- Keep in House office (Saves Time)

- Saves Transportation Time.

- High Precision

- Sturdy Construction

- Longer working Life

- Smooth Performance

- Both Shafted and Hollow Roller to be granulate

Final Thought,

So, this is Rubber Roller Grinding Machine from its introduction to features. Hopefully, you get complete details about it and how it uses in the textile industry. At, Arvind Rubber, we provide rubber roller grinding machine for the industrial industry. Our machine is innovatively designed which not require any operator so that you can use it without any help.

.png)

.png)

You did a very good submission and research about the topic.

ReplyDeleteRubber rollers - https://rubber-

roller.in/